Rubber industry:

Carbon black powder is one of the most important additives in the rubber industry. It can improve the mechanical strength, wear resistance, weather resistance and electrical conductivity of rubber products.At the same time, carbon black powder can also reduce the cost of rubber products and increase production efficiency.

Ink industry:

Carbon black powder is widely used in ink production, which can make the ink darker, dry faster and reduce costs.

Carbon black powder can also increase the gloss of the ink, reduce the printing viscosity of the ink, and make the printing effect clearer.

Paint industry:

Carbon black powder can improve the dye dispersion of the paint, increase the hiding performance of the paint, and also improve the durability and anti-corrosion of the paint.

In the field of automobile manufacturing, carbon black powder is also widely used in automobile primers and coatings to improve their weather resistance and wear resistance.

Other industrial areas:

Carbon black powder can also be used in plastics, electronics, environmental protection and other fields. In the plastics industry, carbon black powder is used as a colorant and filler in plastic materials to increase their strength and durability. In the electronics industry, carbon black powder is used as a resistive material and plays an important role in electronic components. In the field of environmental protection, carbon black powder can be used to purify water and air.

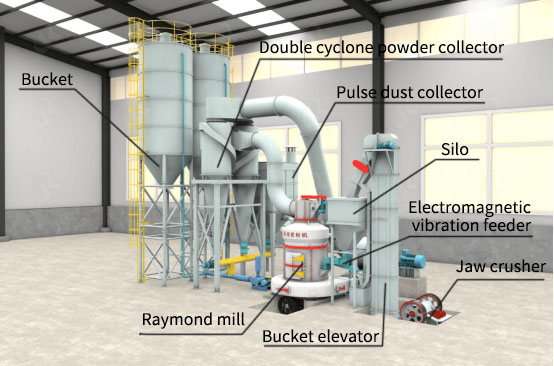

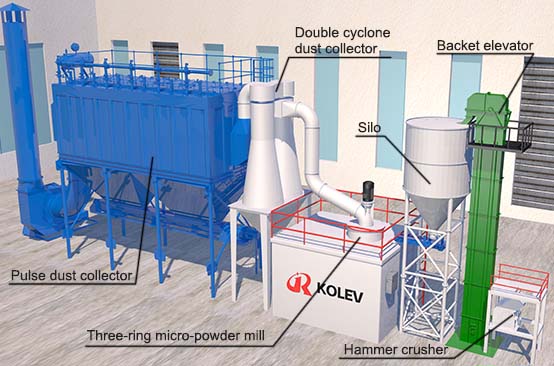

Grinding Mill Machine

Working Principle

Cass

Calcium carbonate grinding production line

Calcium carbonate grinding production line

Dolomite Ultrafine Grinding Project

Dolomite Ultrafine Grinding Project

Gypsum Calcination Grinding Production Line Site

Gypsum Calcination Grinding Production Line Site

+86 166-3801-7614

+86 166-3801-7614