-

Applicable materialsCement, limestone, gypsum, calcium carbonate, fly ash, feldspar, kaolin, dolomite, silica sand, quartz, copper ore, etc.grinding of various ores and other grinding materials.

-

Output size0.3mm-0.045mm (50-325mesh)

-

Feed size≤25mm

-

Capacity1.5-338t/h

Applicable Material

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Ore: including various metallic ores and non-metallic ores, such as iron ore, copper ore, gold ore, bauxite, quartz sand, etc. Ball mill can be used for fine crushing of ore and pretreatment before mineral processing.

Cement and building materials: Ball mill plays an important role in cement production and is used to produce cement of different grades. In addition, it is also used in the manufacture of other building materials products, such as gypsum, lime, fly ash,etc.

Ceramic raw materials: In the ceramic industry, ball mills are used to grind kaolin, quartz, feldspar and other raw materials into the required fineness to prepare ceramic slurry or porcelain mud.

Chemical raw materials: In the chemical industry, ball mills are used to grind various chemical raw materials, such as pigments, dyes, coatings, fertilizers, etc., to meet the production process requirements for material fineness.

Glass raw materials: Ball mills can be used in the glass manufacturing industry to grind quartz sand, feldspar, limestone and other raw materials into particle sizes suitable for glass production.

Non-metallic ores: such as graphite, talc, barite and other non-metallic ores, the ball mill can grind them into the required fineness to meet the application needs of different industries.

Product Features

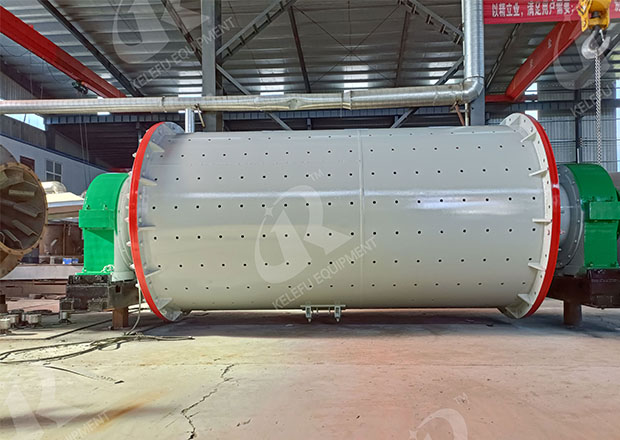

Simple structure, smooth operation

There is no inertia impact, the equipment runs smoothly, and reduces the downtime and maintenance time of the mill, improving the efficiency.Parts wear resistant, long life

Using high quality plate, lining can be replaced, rotary gear using casting gear hobbing processing, the cylinder body is inlaid with wear-resistant lining plate, has good wear resistance.Closed system is adopted to reduce dust

Ball mill and classifier form closed system, negative pressure conveying, small dust, green environment protection.Reliable operation, energy saving effect is remarkable

The bearing body is lubricated by grease, which greatly reduces friction resistance, and the fuel consumption is extremely low and the operation is more convenient.Process Flow Chart

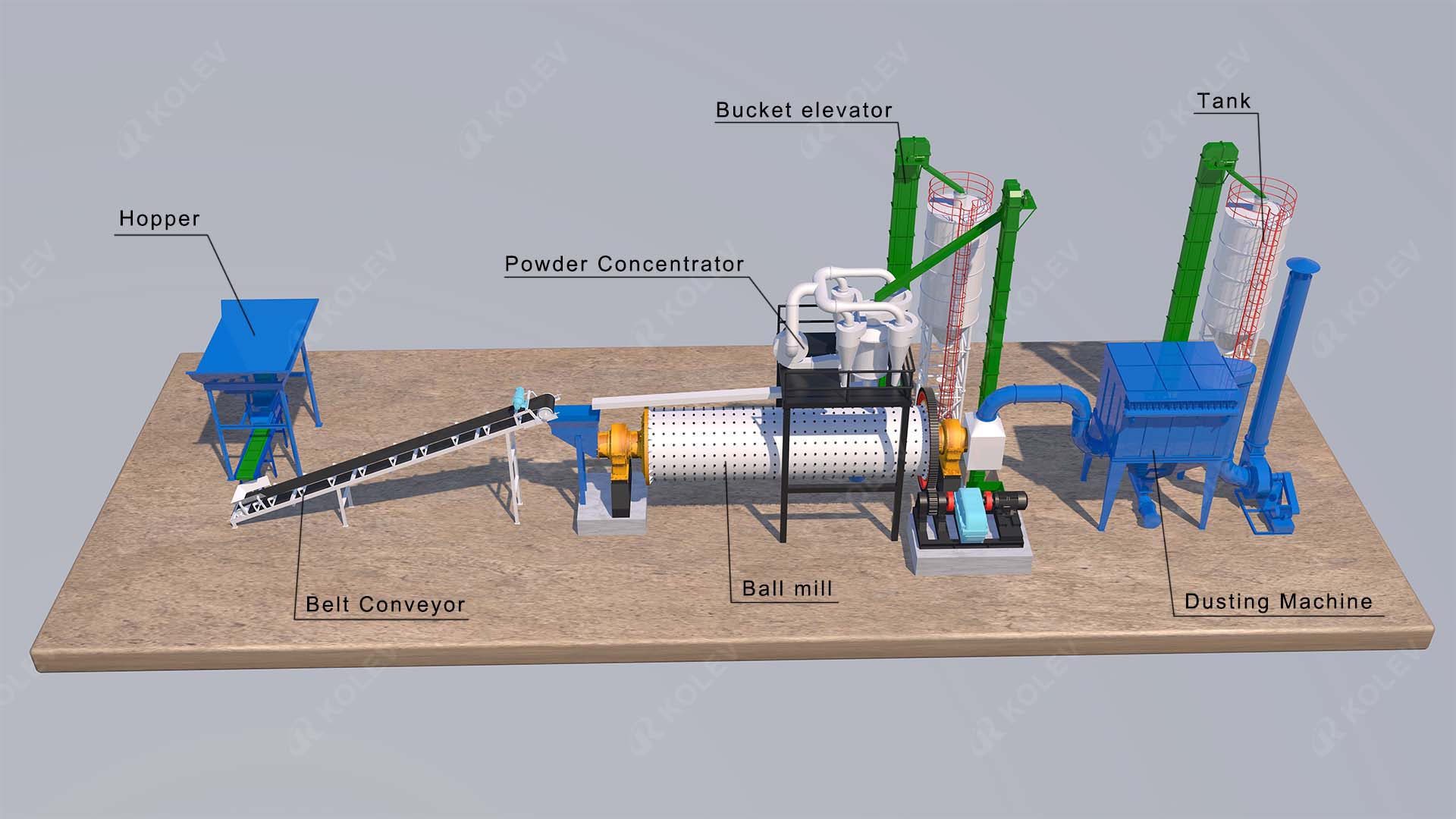

1.The materials that meet the grinding particle size are unloaded into the large silo by the loader. A weighing and metering feeding device (belt metering scale) is arranged under the silo. The device is controlled by a microcomputer and automatically adjusts the feeding amount according to the capacity input parameters.

2.In order to ensure that the mill meets the production standards and reduces the consumption of grinding bodies, a permanent magnetic iron remover is suspended on the feeding belt conveyor to remove metal (physical iron) impurities in the raw materials.

3.This set of grinding scheme adopts a closed-flow (circular flow grinding) grinding process, that is, the mixed powder discharged from the ball mill first enters the powder selection machine for air selection, the fine ash directly enters the finished product warehouse, and the coarse ash returns to the ball mill for secondary grinding, thus forming a closed-loop grinding system.

4.Although the investment in the circle flow grinding system is larger, the fineness (particle size ratio) of the product is uniform, the quality is stable, and the output is much higher than that of the same model ball mill.

Technical Parameter

| Specification | Rotary speed(r/min) | ball load (t) |

feed size(mm) | discharge size (mm) | output capacity (t/h) |

Power (kw) |

weight (t) |

| Ф900×1200 | 36-38 | 1.1 | <20 | 0.074-0.4 | 0.4-1.1 | 11 | 4.21 |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×2100 | 36-38 | 1.8 | <20 | 0.075-0.89 | 0.6-1.5 | 18.5 | 6.66 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×2400 | 30 | 7 | <25 | 0.074-0.4 | 2.8-6.5 | 55 | 15.43 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2--5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3--6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4--10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | According To The Technological Conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | According To The Technological Conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | According To The Technological Conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

Company Profile

Kolev Equipment Technology Co., Ltd. is a large-scale private technology enterprise. The company is committed to the research and development, production and sales of technical equipment for the mining and metal ore industries. It has been deeply involved in the ultra-fine grinding, industrial drying and crushing sand making industries for many years. We can provide you with Provide intelligent solutions and mature supporting products, focusing on the development of various powder equipment, complete powder production lines, drying production lines, sand and gravel line equipment and projects.Products are sold to 160 countries and regions and are well received by customers.

Kolev Equipment has always been adhering to the business philosophy of surviving by quality and developing by credibility, striving to win the trust of customers with high-quality products and perfect after-sales service, and create a brilliant future for Kolev.

+86 166-3801-7614

+86 166-3801-7614