1.Building materials: Feldspar powder can be used as an additive for building materials, such as cement, concrete, gypsum board, etc. It increases the material's strength, durability and resistance to cracking.

2.Ceramics and glass industry: Feldspar powder is one of the important raw materials for ceramics and glass products. As a flux, it can lower the sintering temperature and improve the transparency and gloss of the product.

3.Plastic and rubber industry: Feldspar powder can be used as filler and reinforcing agent in plastic and rubber products. It can improve the hardness, wear resistance and anti-aging properties of products.

4.Refractory materials: Feldspar powder has good fire resistance and thermal stability, so it can be used to make refractory materials, such as refractory bricks, refractory coatings and refractory fibers, etc.

5.Coatings and paints: Feldspar powder can be used as a filler in coatings and paints to improve the covering power, smoothness and durability of the coating.

6.Cosmetics and medicine: Feldspar powder is often used as filler, thickener and oil absorber in cosmetics to improve the texture and durability of the product. In the pharmaceutical field, it can be used as a carrier and diluent for drugs.

7.Agriculture: Feldspar powder is rich in calcium, magnesium and other minerals, and can be used as fertilizer to supplement trace elements in the soil and improve the yield and quality of crops.

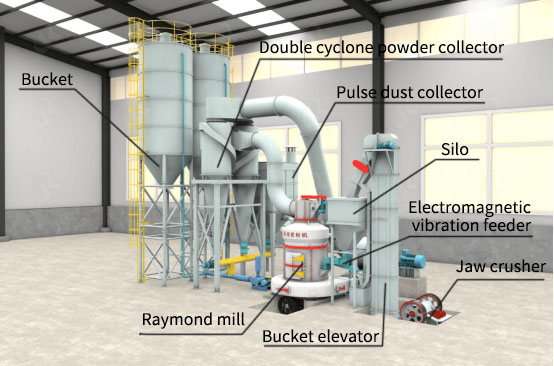

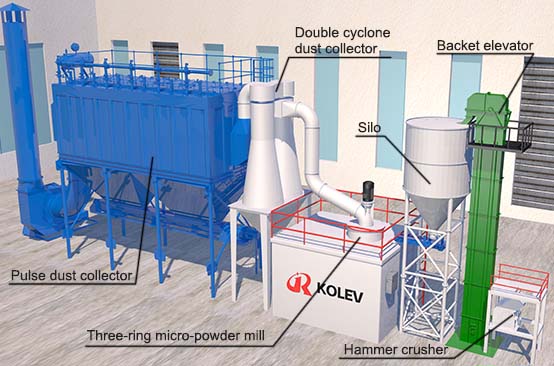

Grinding Mill Machine

Working Principle

Cass

Calcium carbonate grinding production line

Calcium carbonate grinding production line

Dolomite Ultrafine Grinding Project

Dolomite Ultrafine Grinding Project

Gypsum Calcination Grinding Production Line Site

Gypsum Calcination Grinding Production Line Site

+86 166-3801-7614

+86 166-3801-7614