Refractory materials: Graphite and its products have the properties of high temperature resistance and high strength. They are mainly used in the metallurgical industry to make graphite crucibles. They are often used as protective agents for steel ingots and as linings for metallurgical furnaces in steelmaking.

Conductive materials: In the electrical industry, graphite powder is used to make electrodes, brushes, carbon rods, carbon tubes, positive electrodes of mercury current flow devices, etc. In addition, it is also used in the manufacture of graphite gaskets, telephone parts, coatings for television picture tubes, etc.

Wear-resistant lubricating materials: Graphite is often used as a lubricant in the machinery industry. Especially under high-speed, high-temperature, and high-pressure conditions, graphite wear-resistant materials can replace lubricating oil. For example, many equipment conveying corrosive media use graphite materials to make piston cups, sealing rings and bearings, and do not need to add lubricating oil during operation.

Other uses: Graphite powder also has good chemical stability and is widely used in petrochemical, hydrometallurgy, acid and alkali production, synthetic fibers, papermaking and other industrial fields. In addition, graphite powder can also be used in processes such as casting, sand foundry, molding and high-temperature metallurgy. For example, as a casting mold for glass products, it can improve the dimensional accuracy and surface finish of castings.

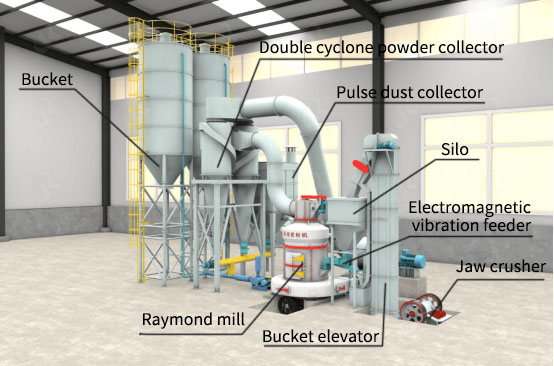

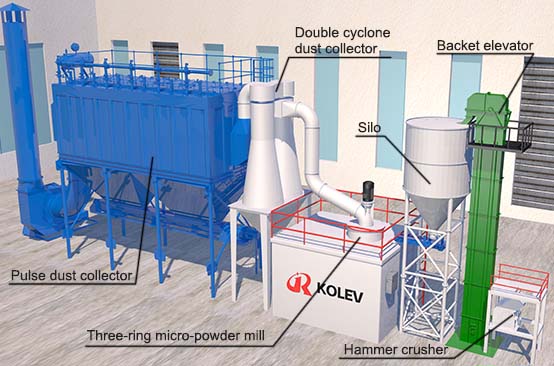

Grinding Mill Machine

Working Principle

Cass

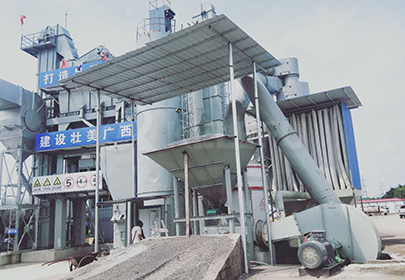

Calcium carbonate grinding production line

Calcium carbonate grinding production line

Dolomite Ultrafine Grinding Project

Dolomite Ultrafine Grinding Project

Limestone Grinding Powder Processing Project

Limestone Grinding Powder Processing Project

+86 166-3801-7614

+86 166-3801-7614