-

Applicable materialsCalcium carbonate,Calcite,Marble,Dolomite,Kaolin,Barite,Gypsum,Silica,Mica

-

Input size20MM

-

Output size0.074-0.005mm

-

Capacity1-30T/H

Applicable Material

Calcium carbonate grinding plant processes natural calcium carbonate ores (calcite, marble, chalk or limestone) through crushing, grinding, classification and surface modification techniques to produce high-value powders of different fineness. With our turnkey solutions, you can produce:

Calcium carbonate powder of 800mesh to 2500 mesh(0.019-0.005mm) is generally used in paints, coatings, inks, PVC, paper coatings, artificial leather, engineering plastics, amino film plastics, wires and cables and other industries.

Product Features

High grinding efficiency andconvenient fineness adjustment

It has the advantages of continuousproduction, large production capacity,high grinding efficiency, vertical cageseparator head, uniform fineness offinished products, easy to adjust finenessand small energy loss.Strong adaptability

Strong adaptability to materials, can grinda variety of Mohs hardness is not greaterthan 7 non-metallic ores.Green environment protection

Pulse dust collection system, strong dustcleaning effect, all the positive pressureparts of the main engine are sealed,basically realize no dust processingworkshop.Fewer transmission parts, lowmaintenance costs

The equipment has compact structure,less transmission parts, low maintenancecost, stable operation and easyinstallation.Working Principle

1.Crushing: Large stone are crushed through jaw crushers

2.Grinding: The core process, small pieces of ore are ground into 325 to 2500 mesh fine powder.

3.Classification: The powder materials pass through the classifier. Centrifugal force and airflow separate the qualified fine powder, while the coarse powder is sent back to the grinding machine for further grinding. This is a crucial step in controlling the fineness and particle size distribution of the product.

4.Surface modification (optional): To enhance the compatibility, dispersion, or hydrophobicity of calcium carbonate powder with polymer materials (such as plastics, rubber, etc.), surface treatment is sometimes carried out.

5.Finished product processing: The qualified fine powder is collected by the cyclone separator and the bag-type dust collector, and then enters the finished product storage area. Packaging is carried out according to customer requirements

6.Dust Removal and Environmental Protection: During the entire production process, a large amount of dust will be generated. The factory must be equipped with a complete dust removal system to meet environmental protection requirements.

Technical Parameter

| Model | KL500 | KL650 | KL780 | KL980 | KL1100 | KL1450 | KL1760 | KL1950 | KL2100 |

| Handling Ability (t/h) | 0.5-2 | 0.5-2.5 | 1-3 | 1.5-4 | 2-6 | 6-10 | 8-20 | 15-30 | 20-40 |

| Main Motor Power(kw) | 7.5 | 15 | 18.5 | 30 | 45 | 90 | 132 | 185 | 220 |

| Fan power(kw) | 5.5 | 11 | 15 | 22 | 37 | 90 | 132 | 185 | 220 |

| Analyst power(kw) | 1.1 | 1.1 | 2.2 | 2.2 | 5.5 | 7.5 | 22 | 37 | 45 |

| Rotate Speed(r/m) | 120 | 120 | 120 | 120 | 120 | 90 | 90 | 90 | 90 |

| Diameter of Grinding Ring(mm) | 500 | 650 | 780 | 980 | 1100 | 1450 | 1760 | 1950 | 2100 |

| Diameter of Grinding Roll(mm) | 150 | 180 | 260 | 300 | 320 | 400 | 450 | 570 | 630 |

| Maximum Feed(mm) | 15 | 15 | 15 | 20 | 25 | 30 | 30 | 40 | 40 |

| Finished Particle Size(mm/mesh) |

1.6 ------ 0.045mm (16-325 Mesh) |

1.6------0.023mm (16-600mesh) |

|||||||

| Weight(t) | 1.8 | 2.8 | 3.8 | 6.5 | 14.5 | 26 | 48 | 65 | 85 |

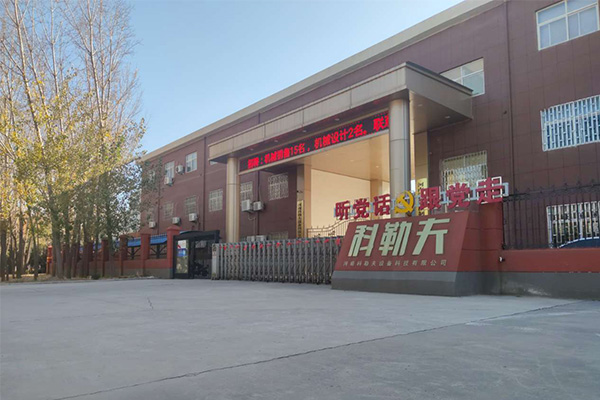

Company Profile

Kolev Equipment Technology Co., Ltd. is a large-scale private technology enterprise. The company is committed to the research and development, production and sales of technical equipment for the mining and metal ore industries. It has been deeply involved in the ultra-fine grinding, industrial drying and crushing sand making industries for many years. We can provide you with Provide intelligent solutions and mature supporting products, focusing on the development of various powder equipment, complete powder production lines, drying production lines, sand and gravel line equipment and projects.Products are sold to 160 countries and regions and are well received by customers.

Kolev Equipment has always been adhering to the business philosophy of surviving by quality and developing by credibility, striving to win the trust of customers with high-quality products and perfect after-sales service, and create a brilliant future for Kolev.

+86 166-3801-7614

+86 166-3801-7614